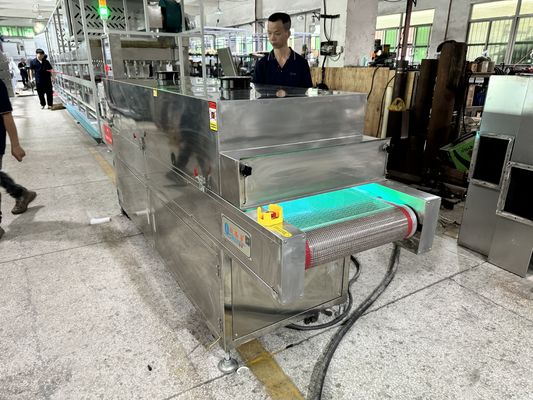

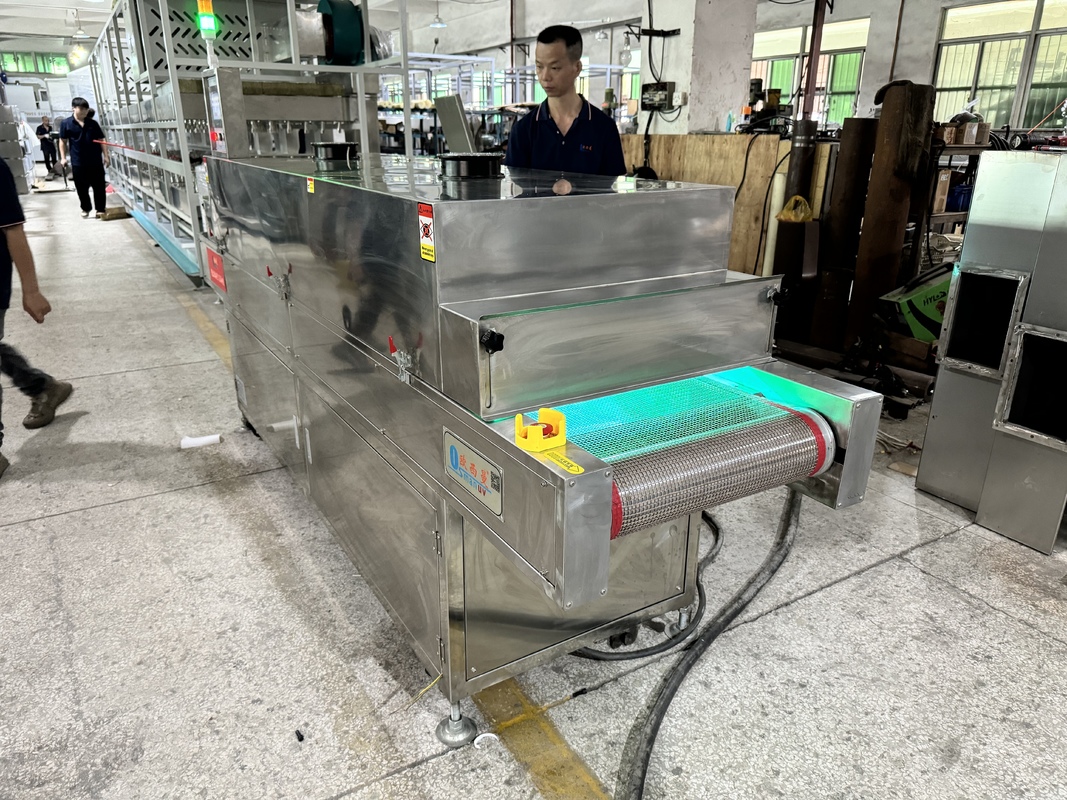

Túnel transportador UV-C de alta eficiência para esterilização contínua da superfície de alimentos | Personalizável para produtos embalados

Detalhes do produto:

| Lugar de origem: | China |

| Marca: | OSMANUV |

| Certificação: | ISO9001 |

| Número do modelo: | OSM-SJ-1320 |

Condições de Pagamento e Envio:

| Quantidade de ordem mínima: | 1 CONJUNTO |

|---|---|

| Preço: | Negociável |

| Detalhes da embalagem: | Caixa de madeira |

| Tempo de entrega: | 30 a 45 dias |

| Termos de pagamento: | T/T |

| Habilidade da fonte: | negociação |

|

Informação detalhada |

|||

| Peso: | 5kg | Recursos de segurança: | Capa protetora UV e desligamento automático |

|---|---|---|---|

| Faixa de controlo do temporizador: | 0-99min | Intensidade da irradiação: | ≥ 90mw/cm2 |

| Velocidade do transportador: | 25 ~ 80m/min | Doença: | novo |

| Faixa de controle de temperatura: | 0-99°C | energiaConsumo: | 150W |

| Destacar: | Túnel transportador UV-C para esterilização de alimentos,Esterilização UV-C personalizável para produtos embalados,Máquina de irradiação UV de alta eficiência |

||

Descrição de produto

Túnel transportador UV-C de alta eficiência para esterilização contínua da superfície de alimentos | Personalizável para produtos embalados

Descrição do produto:

Nosso túnel de esterilização por transportador UV-C de nível industrial foi projetado para fornecer desinfecção não térmica e sem produtos químicos para superfícies de alimentos e embalagens primárias. Utilizando lâmpadas UV-C germicidas de alta saída, reduz efetivamente microrganismos patogênicos e de deterioração (como E. coli, Salmonella, Listeria) para aumentar a segurança e a vida útil do produto. O sistema apresenta um altamente personalizável gabinete e correia transportadora de aço inoxidável para se encaixar perfeitamente nos fluxos de produção existentes.

Composição da linha de produção:

-

Seção do transportador de entrada (sincronizável)

-

Túnel de processo de aço inoxidável com intertravamentos de segurança

-

Conjuntos de lâmpadas UV-C germicidas de alta saída (superior e inferior)

-

Personalizável Câmara refletora para intensidade máxima

-

Sistema de acionamento de controle de velocidade variável

-

Sensores de monitoramento de intensidade UV em tempo real

-

Sistema de ventilação de exaustão (opcional)

-

Seção do transportador de saída

-

Painel de controle principal com tela sensível ao toque HMI

Parâmetros técnicos:

| Categoria de parâmetro | Detalhes e especificações |

|---|---|

| Tecnologia de esterilização | UV-C germicida de onda contínua (254nm) ou luz pulsada (Personalizável) |

| Dose UV efetiva | Ajustável, tipicamente 10 - 100 mJ/cm² (Personalizável com base na velocidade da correia) |

| Tipo de correia transportadora | Correia de malha ou sólida de grau alimentício aprovada pela FDA; largura personalizável (por exemplo, 300 mm, 600 mm, 1000 mm) |

| Velocidade da correia transportadora | Variável, 0,1 - 5 metros/minuto (a velocidade determina a dose UV) |

| Configuração da lâmpada | Conjuntos de lâmpadas modulares; número e potência personalizável |

| Requisitos de energia | 380V / 50Hz ou personalizável para os padrões regionais (por exemplo, 480V / 60Hz) |

| Sistema de controle | CLP com IHM; registro de dados; monitoramento automático da vida útil da lâmpada |

| Material de construção | Aço inoxidável 304 ou 316 (peças de contato) |

| Recursos de segurança | Intertravamentos de segurança, janelas de visualização com bloqueio UV, desligamento automático na abertura da porta |

Aplicação:

Ideal para descontaminação de superfície de produtos de panificação, produtos frescos, carnes, queijos, sushi, refeições prontas para consumo, bem como para o tratamento de materiais de embalagem como bandejas, embalagens tipo concha, garrafas e filmes antes do enchimento.

Personalização:

Nós fornecemos extensa personalização para atender às necessidades específicas do processo. As opções incluem largura/comprimento do transportador, tipo de correia, intensidade e layout da lâmpada UV, integração com equipamentos a montante/a jusante e acabamentos de materiais (por exemplo, classificação IP65 para zonas de alta higiene).

Recurso:

-

Sem produtos químicos e sem resíduos: Seguro para contato com alimentos, sem resíduos químicos ou alteração do sabor.

-

Baixo custo operacional: Eficiente em termos de energia em comparação com os métodos térmicos; manutenção mínima.

-

Efeito instantâneo: Os microrganismos são inativados instantaneamente após a exposição na dose correta.

-

Processo validável: Permite a validação do ponto de controle crítico (CCP) com monitoramento da dose.

-

Design higiênico: Superfícies lisas, fáceis de limpar e manter.

Suporte e serviços:

O pacote de suporte abrangente inclui supervisão da instalação, treinamento operacional, assistência ao protocolo de validação de desempenho, fornecimento de peças de reposição e contratos de manutenção preventiva.

Embalagem e envio:

O equipamento é embalado com segurança em caixas de madeira à prova de intempéries com escoramento interno. Os termos de envio padrão são FOB, com opções CIF/DAP disponíveis mediante solicitação.

Perguntas frequentes:

-

P: A UV-C afeta o sabor, a cor ou os nutrientes dos alimentos?

-

R: Quando usado em doses apropriadas para tratamento de superfície, a UV-C tem impacto mínimo ou nenhum nas qualidades sensoriais ou nutricionais da maioria dos alimentos.

-

-

P: Este sistema pode ser integrado à minha linha de embalagem existente?

-

R: Sim. O design modular e personalizável permite-nos adaptar a entrada/saída, a altura do transportador e a velocidade para corresponder perfeitamente à sua linha.

-

-

P: Como a dose UV efetiva é controlada e monitorada?

-

R: O sistema usa sensores UV calibrados e controle PLC. A dose é controlada ajustando a velocidade do transportador e é registrada para validação do processo.

-

-

P: Existem preocupações de segurança em relação ao vazamento de radiação UV?

-

R: Não. A câmara é totalmente fechada com intertravamentos de segurança que cortam instantaneamente a energia das lâmpadas UV se qualquer painel de acesso for aberto durante a operação.

-

-

P: Qual é o prazo de entrega para um sistema configurado sob medida?

-

R: O prazo de entrega varia com base no nível de personalização. Os modelos padrão têm prazos de entrega mais curtos, enquanto os sistemas totalmente personalizados exigem engenharia detalhada. Fornecemos um cronograma do projeto após a finalização das especificações.

-